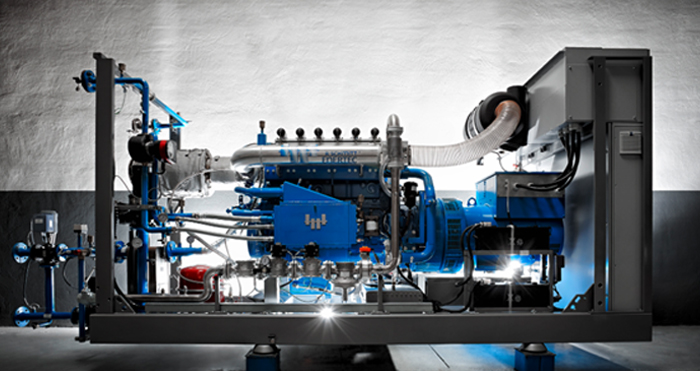

E2P Plus Gas Genset

E2P Plus Gas Gensets – Reliable and Efficient with Lean Burn Technology

E2P Plus brand of Gas Gensets is based on the state-of-the-art European/German Engine platform. E2P Plus gas gensets are equipped with highly efficient R Schmitt Enertec Gas Engines. R Schmitt Enertec GmbH (RSE), with over 40 years of experience in the design, development, and production of gas engines is one of the world’s renowned gas engine manufacturers worldwide. Unlike many other manufacturers in this segment, RSE exclusively specializes in gas engines. The factory accommodating in-house Research and Development, Sales, Service, and Manufacturing is in Mending, Germany.

Our E2P Plus Gas Gensets range from 140 – 125 KWe are specially developed and manufactured for use with different gases. In addition to Natural Gas and Biogas, the engine can also run on wood gas and other special gases. These gas gen-sets come with modern 4-valve technology to provide even higher efficiency.

E2P Plus Gas Gensets are available in the following configurations.

- Generators Set with remote radiator. For applications with no demand for thermal energy.

- Generators Set with heat recovery from engine jacket water. For applications with lower thermal demand or direct use of hot exhaust gases.

- Cogenerator (Combined Heat and Power unit) with heat recovery from jacket water and exhaust. For applications with high demand for thermal energy.

E2P Plus Gas Gensets – Basic features

- Electric Power Range 140 kWe to 500 kWe.

- Thermal Power Range 140 kWe to 500 kWe.

- Up to 42.7 % electrical efficiency.

- Up to 91.4 % overall efficiency.

- Compact Design.

- Plug and Play type.

- Low noise <70db(A) with acoustic enclosure.

- Fuel options: Natural Gas, Biogas, Wood Gas, and other special gases.

Our ENERGIN® GEN+ units are compact cogeneration plants with heat recovery from the jacket water. The innovative design allows an easy and space-saving installation. All major components like the gas engine generator unit, heat exchanger, circulation pumps, and control cabinet are factory mounted on a common frame. The gas engines of the in-house M-series are the core of our units in the electrical power range of 115 – 500 kW. The engines are specially developed and manufactured by us for the use with different gases. In addition to natural gas and biogas, the engines can also run with LPG, wood gas, and other special gases. For the latest engine generation, we rely on the modern 4-valve technology to provide even higher efficiency. With an optional sound attenuating enclosure, that is mounted on the base frame, the sound pressure level can be reduced to less than 70 dB(A) in 1 m distance. For customers with steam requirements, the ENERGIN® GEN+ can also be supplied in conjunction with a steam boiler. For higher heat demands we recommend our ENERGIN® CHP units with additional heat recovery from the exhaust gas of the engine.

GEN+ Basic scope of supply

- 4-stroke gas engine coupled with double bearing alternator mounted on a common frame.

- Sound attenuating enclosure with air ventilation, mounted on a common frame.

- Heat recovery from jacket water, lube oil, and if applicable 1st stage mixture cooling.

- Remote radiator for 2nd stage (if applicable).

- Remote radiator for jacket water, lube oil, and if applicable 1st stage mixture cooling.

- ENERSCREEN® control system with 12″ touch panel for engine, alternator, and auxiliaries, set mounted in switchboard, with synchronizing and alternator protection functions.

- Generator circuit breaker, set mounted in the switchboard.

- Lube oil system designed for long oil change intervals.

- Electric pre-lubrication pump with changeover valve.

- Exhaust silencer in single or two-stage design, supplied loose.

The basic features are:

- Electric power range 115 – 500 kW

- Thermal power range 98 – 376 kW

- Up to 42,7 % electric efficiency

- Up to 70,2 % overall efficiency

- Low noise option <70 dB(A)

- Plug-and-play type

- Fuel options: Natural gas, Biogas, Wood gas, LPG

Performance Data

>> Natural Gas, 400 V, 50 Hz, 500 mg/Nm3NOx

| Engine Type | E2P+NG-140 | E2P+NG-200 | E2P+NG-250 | E2P+NG-260 | E2P+NG-333 | E2P+NG-400 | E2P+NG-500 |

|---|---|---|---|---|---|---|---|

| Electrical power/kW | 140 | 200 | 250 | 260 | 333 | 400 | 500 |

| Electrical efficiency/% | 38,6 | 41,0 | 41.8 | 41,0 | 41,9 | 42,1 | 42,1 |

>> Biogas, 400 V, 50 Hz, 500 mg/Nm3NOx

| Engine Type | E2P+BG-140 | E2P+BG-200 | E2P+BG-250 | E2P+BG-260 | E2P+BG-333 | E2P+BG-400 | E2P+BG-500 |

|---|---|---|---|---|---|---|---|

| Electrical power/kW | 140 | 200 | 250 | 260 | 333 | 400 | 500 |

| Electrical efficiency/% | 38,6 | 41,0 | 41,8 | 41,0 | 41,9 | 41,1 | 42,1 |

- In view of our constant endevour to improve the quality of our products, we reserve the right to alter or change the specification without prior notice.

- The values given above are for information purposes only and not binding. The information given in the offer is decisive.

Specifications and Dimensions

>> Natural Gas, 400 V, 50 Hz, 500 mg/Nm3NOx

| Engine Type | E2P+NG-140 | E2P+NG-200 | E2P+NG-250 | E2P+NG-260 | E2P+NG-333 | E2P+NG-400 | E2P+NG-500 | |

|---|---|---|---|---|---|---|---|---|

| Length | mm | 3200 | 3200 | 3200 | 4040 | 4040 | 4380 | 4380 |

| Height | mm | 2250 | 2250 | 2250 | 2030 | 2030 | 2030 | 2030 |

| Bore/Stroke | mm | 3200 | 3200 | 3200 | 4040 | 4040 | 4380 | 4380 |

| Width | mm | 1340 | 1340 | 1340 | 1440 | 1440 | 1440 | 1440 |

| Dry weight Genset | Kg | 2920 | 3310 | 3330 | 4090 | 4160 | 4810 | 5590 |

| Bore/Stroke | mm | 130/142 | 170/195 | 170/195 | 170/195 | 170/195 | 170/195 | 170/195 |

| Displacement | dm3 | 11.3 | 11.3 | 11.3 | 15.1 | 15.1 | 22.6 | 22.6 |

| Dry weight Genset | Kg | 2920 | 3310 | 3330 | 4090 | 4160 | 4810 | 5590 |

| Speed | min-1 | 1000 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Mean piston speed | m/s | 7.1 | 7.1 | 7.1 | 7.1 | 7.1 | 7.1 | 7.1 |

>> Biogas, 400 V, 50 Hz, 500 mg/Nm3NOx

| Engine Type | E2P+NG-140/ | E2P+NG-200 | E2P+NG-250 | E2P+NG-260 | E2P+NG-333 | E2P+NG-400 | E2P+NG-500 | |

|---|---|---|---|---|---|---|---|---|

| Length | mm | 3200 | 3200 | 3200 | 4040 | 4040 | 4380 | 4380 |

| Height | mm | 2250 | 2250 | 2250 | 2030 | 2030 | 2030 | 2030 |

| Bore/Stroke | mm | 3200 | 3200 | 3200 | 4040 | 4040 | 4380 | 4380 |

| Width | mm | 1340 | 1340 | 1340 | 1440 | 1440 | 1440 | 1440 |

| Dry weight Genset | Kg | 2920 | 3310 | 3330 | 4090 | 4160 | 4810 | 5590 |

| Bore/Stroke | mm | 130/142 | 170/195 | 170/195 | 170/195 | 170/195 | 170/195 | 170/195 |

| Displacement | dm3 | 11.3 | 11.3 | 11.3 | 15.1 | 15.1 | 22.6 | 22.6 |

| Dry weight Genset | Kg | 2920 | 3310 | 3330 | 4090 | 4160 | 4810 | 5590 |

| Speed | min-1 | 1000 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Mean piston speed | m/s | 7.1 | 7.1 | 7.1 | 7.1 | 7.1 | 7.1 | 7.1 |

- Above details / values are approx. and may change without prior information - Dimension with Acoustic Enclosure

- The values given above are for information purposes only and not binding. The information given in the offer is decisive.